The history of mining – II.

A more sophisticated method of mining was the use of shafts and coves. Garnet diggers did not want to waste their time removing overburden (sometimes 7 metres thick) from the entire surface over the mined area, so they began to dig shafts wide enough to lower a bucket. On the surface, the bucket was connected to a manual winch operated by two people. After the shaft had penetrated the overburden or the upper layers poor in garnets, reaching the pyrope-bearing layers (called “křehoť” or “křemeť”, i.e. a garnet-bearing layer), miners began to dig stopes in all directions from the shaft. The bottom of the stope was identified by a thick layer of compact beige clay in which pyropes do not occur. The ceiling of the stopes was limited by the thickness of the garnet layer. This method of mining was not very safe, as evidenced by the numerous fatal accidents that were recorded. In addition, the entire mining took place in completely incoherent rocks.

The last method of how Bohemian garnets were and still are mined in the Central Bohemian Uplands is quarry mining. Its arrival also finally ended individual unorgani- zed mining. Mining of the deposit after the removal of the overburden consisting of topsoil and subsoil is operated in one mine section using tracked excavators and loaders. The mined material is transported to the Podsedice finishing plant, where the garnet concentrate is obtained using rotary screens and jigs, and this concentra- te is subsequently handpicked and sorted in the Granát cooperative, i.e. directly at the Turnov plant.

A larger screen on which larger garnets selected for further cutting were separated from small pieces that were not taken (i.e. went to waste).

Handpicking at the screen usually only served to check the yield of the current mining.

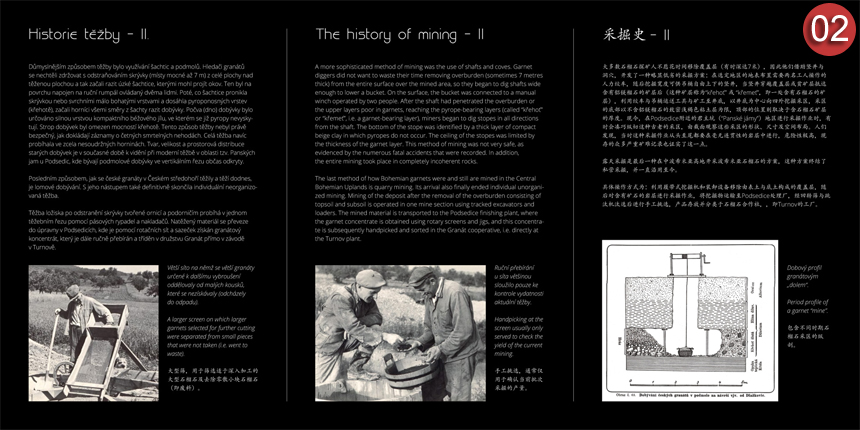

Period profile of a garnet “mine”.